Mastering Project Challenges in Battery Factory Builds

Explore the intricate dance of project management within the booming battery cell production industry, and how to surmount its unique challenges.

Learn more about the rapid expansion of battery cell factories and the race against time in the battery cell production industry. Key industry trends and challenges are highlighted.

"It's a race - and everyone has to be the fastest."

In recent years, the battery cell production industry has experienced unprecedented growth.

As the demand for electric vehicles (EVs) and renewable energy solutions skyrockets, so does the need for efficient and powerful battery cells.

This increase has led to a race between companies and nations to build state-of-the-art battery cell factories.

For project managers, site managers, operations managers, CEOs and other directors working in this space, it is critical to understand the current landscape and the importance of speed and precision in building these factories.

Although expectations for EV sales declined between 2023 and 2024, the growth trend is expected to remain strong. Many investors are sticking to their plans.

This article provides an overview of ongoing projects, industry changes and the competitive situation in the battery cell production industry and emphasizes the need for professional and rapid implementation when setting up these factories.

The following content awaits you:

The battery cell production industry is booming, with numerous projects worldwide, especially in Europe. These projects aim to meet the growing demand for battery cells driven by the automotive, renewable energy and consumer electronics industries. Notable projects include:

For detailed insights into these and other projects, Battery News is an excellent source. In addition, Electrive and PV Magazine provide comprehensive coverage of developments in the battery industry.

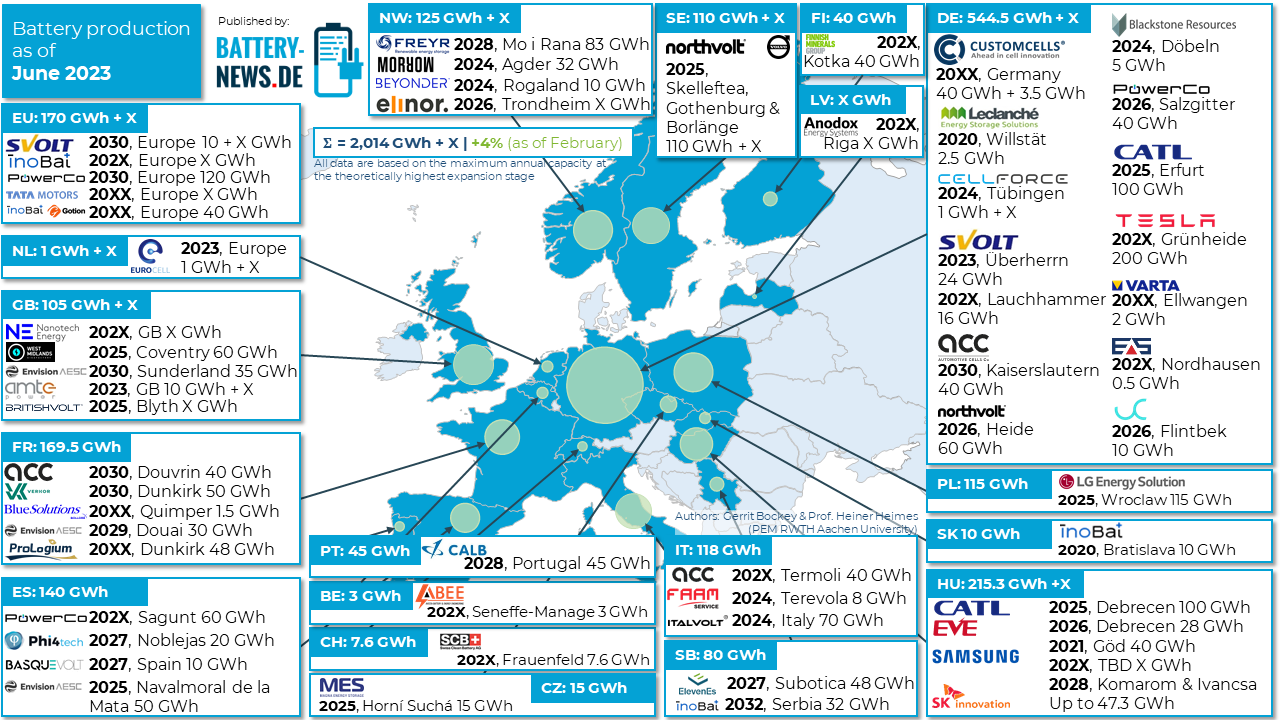

The data is currently changing very quickly. Here is an overview as of June 2023:

Source: battery-news.de (retrieved on June 11, 2024; authors: Gerrit Bockey & Heiner Heimes)

The automotive industry's shift towards electric vehicles is the main driver for increased battery cell production.

Large car manufacturers such as Volkswagen, BMW, Mercedes-Benz, General Motors and Ford have announced ambitious plans to electrify their fleets, creating immense demand for battery cells.

We are also seeing a huge increase in battery-related projects among our customers and can confirm the trend first-hand.

Be it the conversion of body assembly lines, powertrain component plants or pack assembly and assembly lines. At the moment, the entire automotive industry seems to be undergoing a massive transformation.

It is worth noting that Asian OEMs such as Toyota, Hyundai and BYD are also investing heavily in EV technology and thus continuing to drive the growth of the industry.

In comparison to ten years ago, investment in battery technology and production has increased exponentially. The global push for sustainable energy solutions and strict emissions regulations have accelerated this trend.

For example, global investment in battery manufacturing facilities is expected to exceed $500 billion by 2030, reflecting the enormous scale of change in the industry.

The race to build battery cell factories is highly competitive, with companies and regions battling for supremacy.

Asia, particularly China, is a leading player in battery cell production, with companies such as CATL and BYD at the forefront. However, Europe and North America are catching up fast, driven by local demand and government incentives.

However, they remain dependent on leading Chinese machine suppliers for battery production, which requires close cooperation.

Battery cell suppliers and manufacturers are strategically establishing production facilities in key markets around the world.This localization strategy aims to reduce logistical challenges, comply with local regulations and better serve regional markets.

Chinese manufacturers in particular are expanding their global footprint by setting up factories in Europe and North America to secure their market position.

Here is a short list of Chinese cell manufacturers with ambitions in Europe or North America:

Building new battery cell production facilities is a complex task that requires careful project management and tracking. The main challenges include:

We will go into more detail on this topic in another blog post. As soon as it is published, you will find the link here.

Speed and precision in the construction of battery cell factories offer a significant competitive advantage.

Companies that can quickly build and scale their production facilities are better positioned to meet growing market demand and capitalize on emerging opportunities.

Here are some suggestions to achieve faster and more accurate construction:

The battery cell production industry is experiencing significant growth. Recent data shows that over 100 billion dollars have already been invested in battery cell factories worldwide

In Europe alone, over 30 new battery cell factories are expected to be built by 2030.

The number of cell factories worldwide is expected to rise from around 100 at present to over 200 in the next five to ten years.

For those looking for more information on battery technology and production, several key events offer valuable insights:

The battery cell manufacturing industry is at a turning point, with rapid expansion and intense competition shaping the landscape.

For industry players, accelerating and professionalizing the construction of cell factories is not only beneficial, but essential.

By focusing on effective project management, leveraging technological advances and complying with regulatory requirements, companies can gain a decisive advantage in this dynamic market.

As the industry continues to evolve, moving forward requires not only speed, but also precision and strategic planning.

Investment in battery manufacturing is huge, with billions of dollars being poured into new facilities worldwide.

With over 200 cell factories expected to come online in the next ten years, the industry is poised for transformative growth. By attending key industry events and staying on top of the latest trends, stakeholders can better navigate the complexities of this fast-moving industry.

Explore the intricate dance of project management within the booming battery cell production industry, and how to surmount its unique challenges.

Find out how the Industrial Metaverse is redefining project management, collaboration and control in industry - and why this technology is far more...

Discover how the Industrial Metaverse is revolutionizing project management and control in industrial environments—offering game-changing...

You are curious and want to know more about our software, customers and releases? Be the first to know about new updates, interesting success stories or awesome project management hacks. Sign in now!